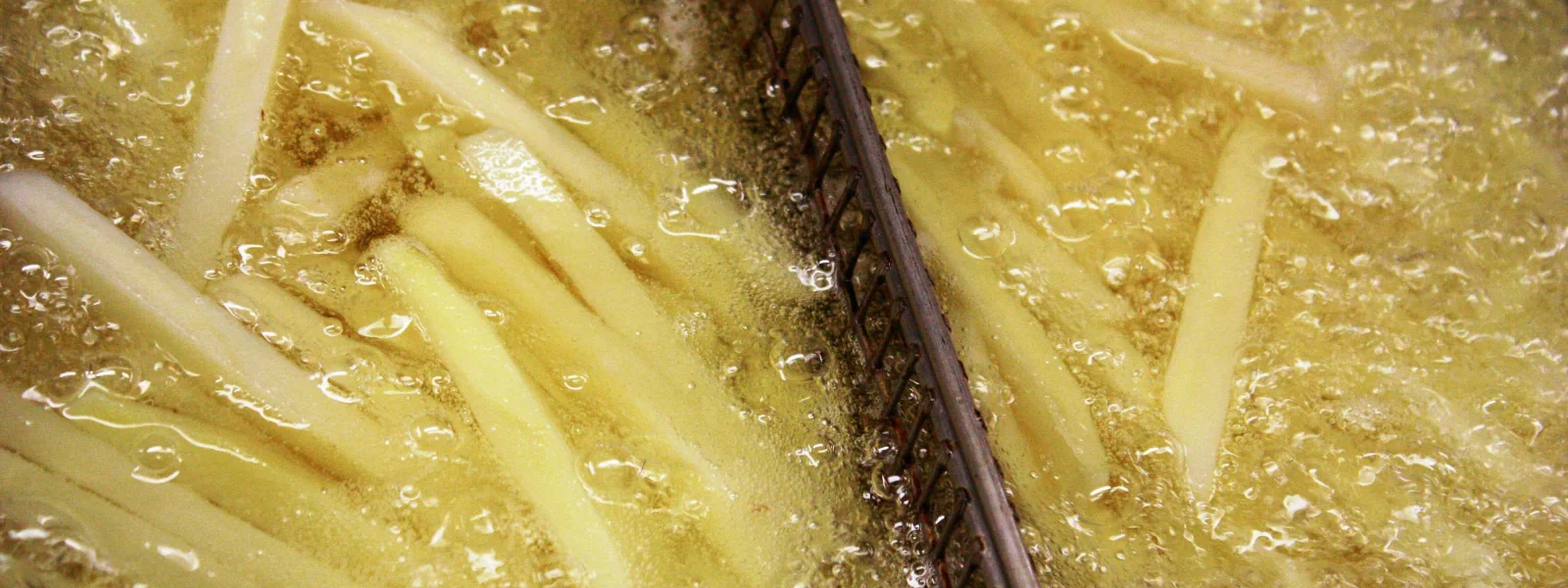

Extending the life of kitchen equipment is a priority for many restaurant owners and chefs who seek to maintain efficiency while minimizing costs. Among the various pieces of equipment in a commercial kitchen, deep fryers play a crucial role due to their frequent use. Over time, these appliances can suffer from wear and tear, leading to reduced performance and potential breakdowns. One effective maintenance strategy that can significantly extend the life of a deep fryer is boiling it out as needed.

Boiling out a deep fryer involves thoroughly cleaning its interior by using water and an appropriate cleaning solution at high temperatures. This process helps remove accumulated grease, carbon deposits, and other residues that can negatively impact the Boiling a deep fryer‘s functionality. By preventing build-up within the machine, boiling out ensures that heat distribution remains even and efficient during cooking processes.

The procedure begins with draining all oil from the fryer once it has cooled down sufficiently to handle safely. After ensuring no residual oil remains in the vat, fill it with water up to the usual oil line or slightly below it. Adding a specialized boil-out cleaner designed for commercial kitchens will aid in breaking down stubborn deposits more effectively than water alone.

Once filled with this solution, turn on the fryer’s heating element until reaching simmering temperatures—typically around 200°F (93°C). Allowing this mixture to simmer for about 20-30 minutes enables thorough penetration into crevices where grease may have solidified over time. During this period, it’s advisable to occasionally scrub accessible areas gently using non-abrasive tools like brushes or pads specifically made for such purposes.

After completing these steps comes draining again—carefully disposing of dirty liquid according to local regulations regarding waste disposal—and rinsing thoroughly multiple times with clean water until all traces of cleaner are eliminated entirely from surfaces inside your appliance’s vat area; any residue left behind could affect food quality adversely if not removed properly beforehand!

Regularly implementing boil-outs as part of routine maintenance schedules offers numerous benefits beyond extending lifespan alone: improved energy efficiency due largely thanks lessened resistance heating elements face when free obstructions exist internally; better-tasting fried foods resulting absence burnt flavors caused old oils mixing fresh batches inadvertently during operations; enhanced safety conditions since reduced risk fire hazards associated excessive grease accumulation present throughout entire system itself too!

In conclusion then – taking proactive measures like conducting periodic boil-outs whenever necessary proves invaluable investment both short term long run alike helping safeguard against unexpected downtimes costly repairs replacements might otherwise become inevitable without proper care attention paid upfront initially instead!